How does an engine actually move a car? Kwik Lessons

Bradley Jando | Monday 26th April 2021 8:40am

We previously talked about all of the different parts of an engine, and how engines work on our recent blog article, which you can find here Ė so the actual process of converting the linear motion of pistons into the rotational motion of the crankshaft is understood. But the question now is: how does all this come together to actually move the car?

The flywheel keeps things running

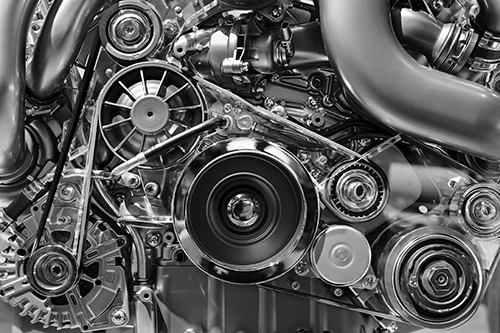

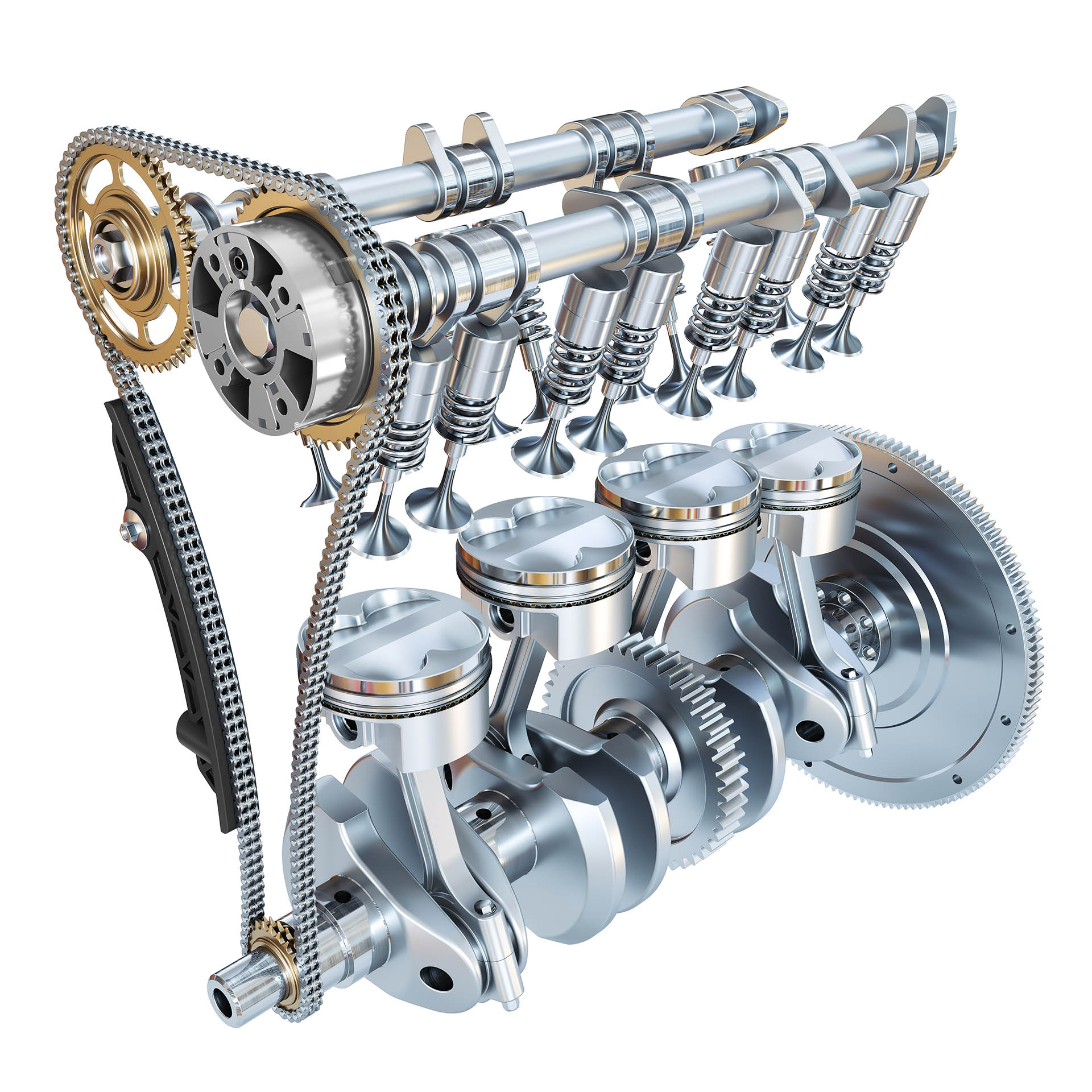

Weíve learned how the motion of the engine cylinders is converted into the rotational motion of the crankshaft. Well, in order to get power out of an engine, that crankshaft is connected to a flywheel. You can see the flywheel on the right of this image:

The flywheel largely helps to smooth the motion of the engine by maintaining rotational inertia. You can see a wonderful example of how an engine runs with and without a flywheel in the video below:

So, as the engine runs, the flywheel spins and evens out the discrepancies between the motion of the cylinders. In theory, you could connect this directly to a few gears and use that to turn some wheels Ė but then you would only ever be able to go or stop by turning the engine on and off. Moreover, you would only be able to drive within a limited speed range. Now, considering the amount of power required to start the engine through a starter motor, you would quickly run your battery down in stop-start traffic.

In order to keep an engine running and let you drive smoothly at different speeds, you need to transmit that power through the transmission system. The first part of that system is the clutch.

The clutch

On the other side of the flywheel is the clutch. This basically connects the rotational motion of the flywheel Ė as well as all its power Ė to the transmission system and then eventually onto the wheels. So that you donít have to start and stop the engine each time you want to change gears Ė which would also be dangerous if not impossible at speed Ė the clutch system lets you engage and disengage the transmission from the flywheel.

When you press the clutch pedal down, a cable is pulled which pulls the clutch plate away from the flywheel. This essentially removes the power transmission from the engine. It acts in the same way as turning the engine on and off but without having to actually turn the engine off.

In the image below, the flywheel is the disc on the left, the clutch is the disc sandwiched between the flywheel and the clutch cover.

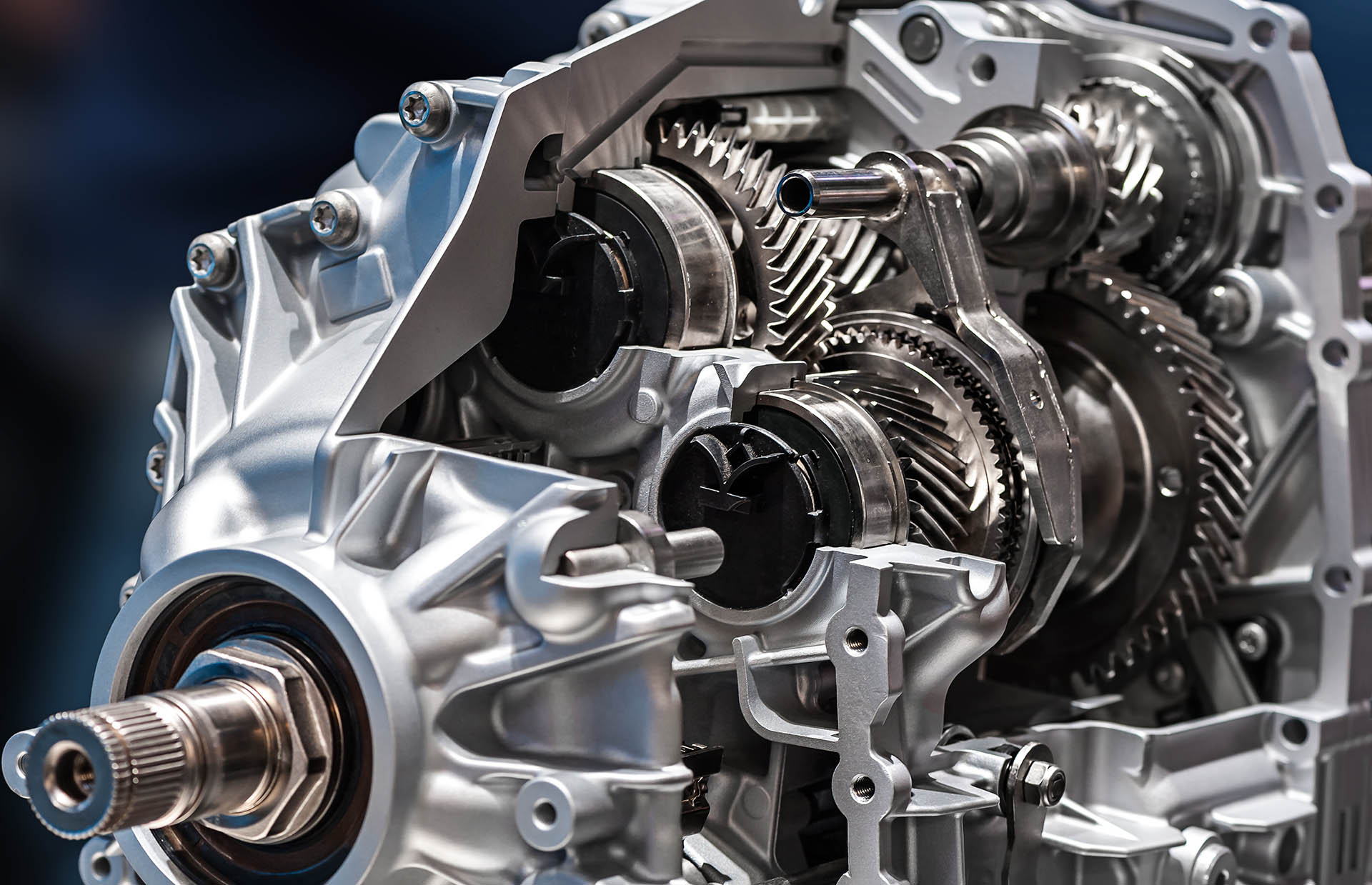

The transmission system

The transmission system, in short, is a relatively complicated system of gears that multiplies or divides the power coming out of the engine. You use your gearbox to change these gears. We could go through gear theory in detail but itís more useful here to simply be aware that the different gears you put your car into convert the power from the engine in different ways.

If you drive, youíll already be aware of this. When youíre in first gear, you canít go very fast but more power is going to the wheels in order to get them going from stationary.

When youíre in neutral, the transmission system isnít connected, so you can take your foot off the clutch (which technically engages the clutch) but your car doesnít stall because thereís no load on the engine.

When you try to engage the clutch in first gear, for example, you need to match the required force by putting more power into the engine (through the accelerator pedal). Now, because the transmission system turns directly with the wheels, if the wheels arenít moving then theyíll stop your engine from moving when the clutch is engaged. This is why your car stalls when you donít get the biting point right.

When your carís already moving, it takes a lot less power to get it moving a little bit more. So itís relatively easy to change gears when youíre going at the general speed to change a gear.

But the question still stands: how does this all go to actually moving the wheels?

The drive shaft and differentials

On the other side of the transmission is the drive shaft. This is a shaft with a hinged connection on either side. Now, the actual construction of a drive shaft can vary dramatically between cars because itís surprisingly difficult to transmit power from the engine across a distance to wheels within the context of driving in the real world.

Think about trying to use a broom from a distance, youíre holding the handle end with one hand and trying to sweep something two meters away. You may be able to do an ok job of it inside, but if youíre trying to do this while moving Ė or if there are any other external factors like wind Ė then it becomes a significantly harder job.

The drive shaft faces a similarly difficult problem. While driving on a road, your car is subjected to a whole host of different forces as it accounts for bumps and unevenness in the road Ė as well as other factors. The drive shaft needs to be rigid in order to effectively transmit the torque from the engine to the wheels, but if itís a single rod then it canít account for any flexing.

Thatís where the hinges come in. They allow the front and end of the drive shaft to move up and down, as well as change angle, within certain parameters while still rotating.

Hereís a great video on how a drive shaft works:

The end of the drive shaft is attached to a component known as a differential. This is like a big cog set at a right angle to the drive shaft Ė so the rotation of the drive shaft is turned into rotation along the axis of the axles, and then the wheels.

An added task of the differential is to be able to account for differences in wheel speed between the left and right side such as when driving through corners.

Now, you may be wondering how this works for both front and back axles. But this is exactly what rear or front wheel drive means! Unless you have a four wheel drive. Only one set of wheels is actually driving the car.

Hopefully, thatís everything you need to know for a general awareness of the drive train system in a car. There are a whole set of different systems and parts here that could take books to explain. But this should have given you a good overall knowledge.

If youíre concerned about an aspect of your carís drive train, donít hesitate to get in touch with your local Kwik Fit Centre.

Any facts, figures and prices shown in our blog articles are correct at time of publication.

Featured Articles

Is it Illegal to Drive With One Headlight?

Saturday 19th July 2025

Wondering if itís illegal to drive with one headlight? Learn about the safety risks and penalties of illegal blown bulbs and why you should fix them promptly.

Air Con in EVs & Hybrids: Experts Answer Your Questions

Monday 30th June 2025

Does air con drain EV batteries? Can you use the air con while charging an electric car? Find out the answers to these questions & more from Kwik Fitís experts.

Why Is Your Car Making a Noise? Fixes & Tips

Friday 13th June 2025

When your car starts making unexpected noises, it can certainly be quite disconcerting; it may be nothing to worry about, but hereís what you need to know.